Vector control of an induction motor, also known as field-oriented control (FOC), is a clever method for precisely controlling torque and speed. Because torque and flux are connected in a typical induction motor, control is less flexible. This is resolved by vector control, which divides the current into two components: one that regulates the torque and the other that regulates the motor’s magnetic flux. This is comparable to the operation of a DC motor, in which torque is managed by armature current and flux by field current. Vector control offers quick response, seamless operation, and excellent efficiency with the use of transforms, sensors, and an inverter. It is extensively utilized in industrial machinery, robotics, electric cars, and renewable energy sources.

How Induction Motor work:

Clarke and Park Transformations-

- Three-phase currents are transformed into two-phase stationary components using the Clarke transformation.

- These elements are rotated into a d-q frame using the Park Transformation.

- The d-axis regulates flow and is in line with the rotor flux.

- The q-axis regulates torque and is perpendicular to flux.

Independent Control-

- Smooth motor functioning is ensured via d-axis current → flux regulation, which maintains a constant magnetic field.

- The motor’s force output is directly controlled by the q-axis current to achieve the necessary speed and load handling.

- Independent control: The motor is extremely responsive, effective, and manageable due to the separation of flux and torque.

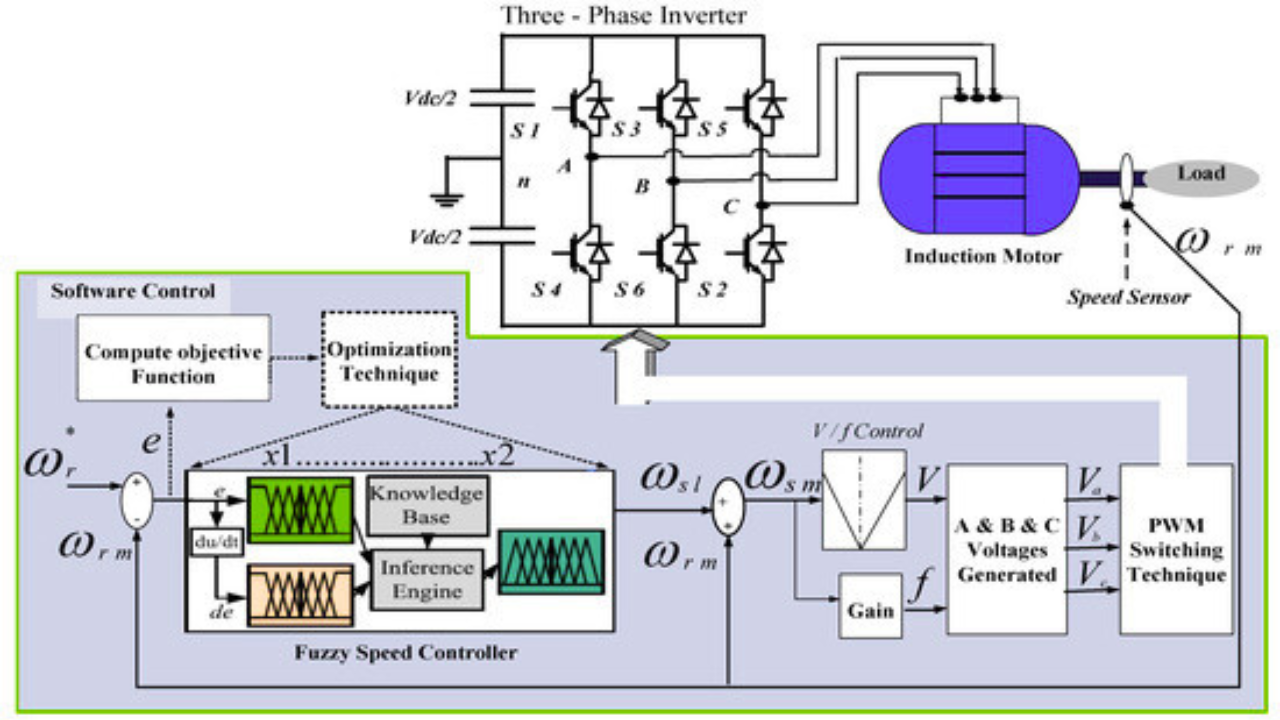

Feedback & Inverter-

- Sensors or estimators: Monitor the rotor’s position and speed continuously.

- Control Algorithm: After processing this feedback, a microcontroller or DSP determines the precise control action.

- Inverter Action: Adjusts voltage and frequency to give the needed torque and speed.

- As a result, motor performance is fluid, accurate, and effective.

Advantages of Induction Motor:

- Fast Dynamic Response: Perfect for applications requiring precise and rapid speed and torque changes, such as robotics, electric cars, and CNC machines.

- High Efficiency: Conserves energy while maintaining outstanding performance across a broad speed range.

- Accuracy and seamless operation in operations requiring stability are guaranteed by precise torque control.

- Improved Low-Speed Performance: It provides more torque and smoother motion at low speeds than conventional V/f (scalar) control.

Applications of Induction Motor:

- Electric vehicles save energy and offer great torque and smooth acceleration.Vector management of induction motors is essential for ensuring smooth and effective operation in electric vehicles (EVs). It enables the motor to react rapidly to demands for braking and accelerating by isolating torque and flux regulation. This guarantees that drivers receive immediate torque for seamless control at different speeds and rapid starts. Additionally, vector control increases efficiency by increasing driving range and battery life. It retains power and stability at high speeds while producing exceptional torque at low speeds. Vector control is perfect for powering contemporary electric vehicles because of its performance, accuracy, and energy efficiency.

- Industrial drives: Provide dependable and controlled power to conveyors, compressors, and pumps.Vector control of induction motors guarantees dependable and effective operation in industrial drives such as pumps, compressors, and conveyors. For these applications to easily handle fluctuating loads, accurate speed and torque control are frequently required. Vector control allows the motor to react quickly to changes, preserving steady performance and minimizing equipment wear. Additionally, it increases energy efficiency, which lowers operating costs in sectors where motors are used for extended periods of time. For industrial processes that require continuous and controlled motion, vector control increases the versatility, dependability, and affordability of induction motors by enabling steady operation at both low and high speeds.

- Automation and robotics: provide precise motion and quick reaction.Vector control of induction motors provides the accuracy and adaptability required for intricate jobs in robotics and automation. Vector control, which individually regulates torque and flux, enables the precise positioning, fluid motion, and fast reactions that robots need. Even at low speeds and with abrupt changes in load, this guarantees steady operation. Consequently, automated systems become more dependable, efficient, and able to execute high-speed or sensitive operations with exceptional accuracy.

- Renewable Energy Systems: Enhances the efficiency of wind turbines and comparable devices.

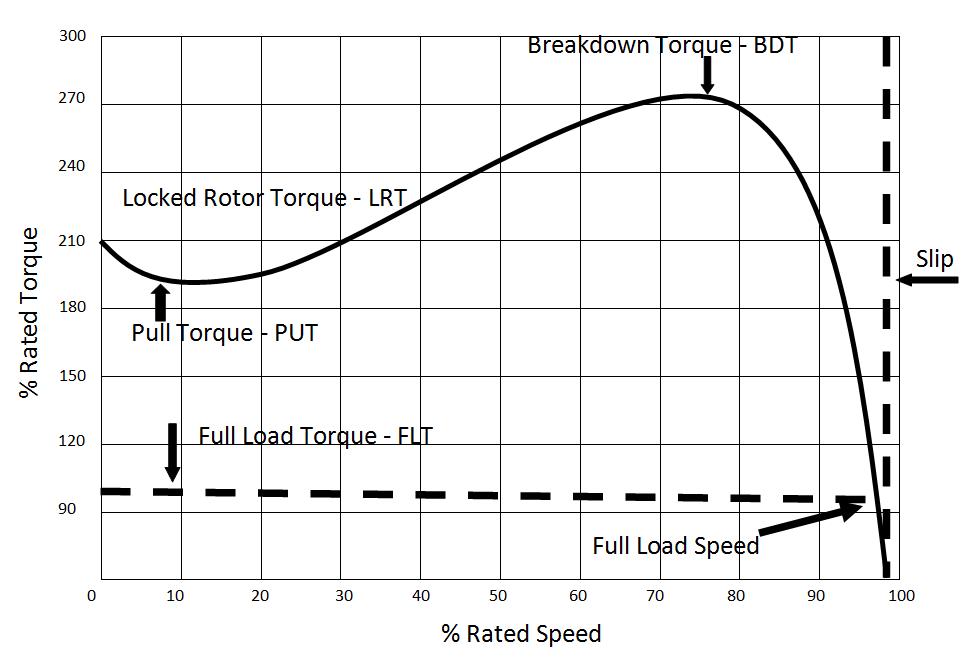

Key Points in Torque–Speed Curve:

At Standstill (0 speed)-

- Rotor slip = 1.

- Torque is relatively high (starting torque).

Acceleration Region–

- As the motor speeds up, torque first increases, reaching a maximum torque (pull-out or breakdown torque) at a certain slip (usually 5–10%).

- This maximum torque is much higher than rated torque.

Stable Operating Region–

- After maximum torque, torque decreases with further speed increase.

- The motor normally operates here, near synchronous speed, with slip around 2–6%.

At Synchronous Speed-

- slip=0

- no relative motion between stator field and rotor, so torque=0