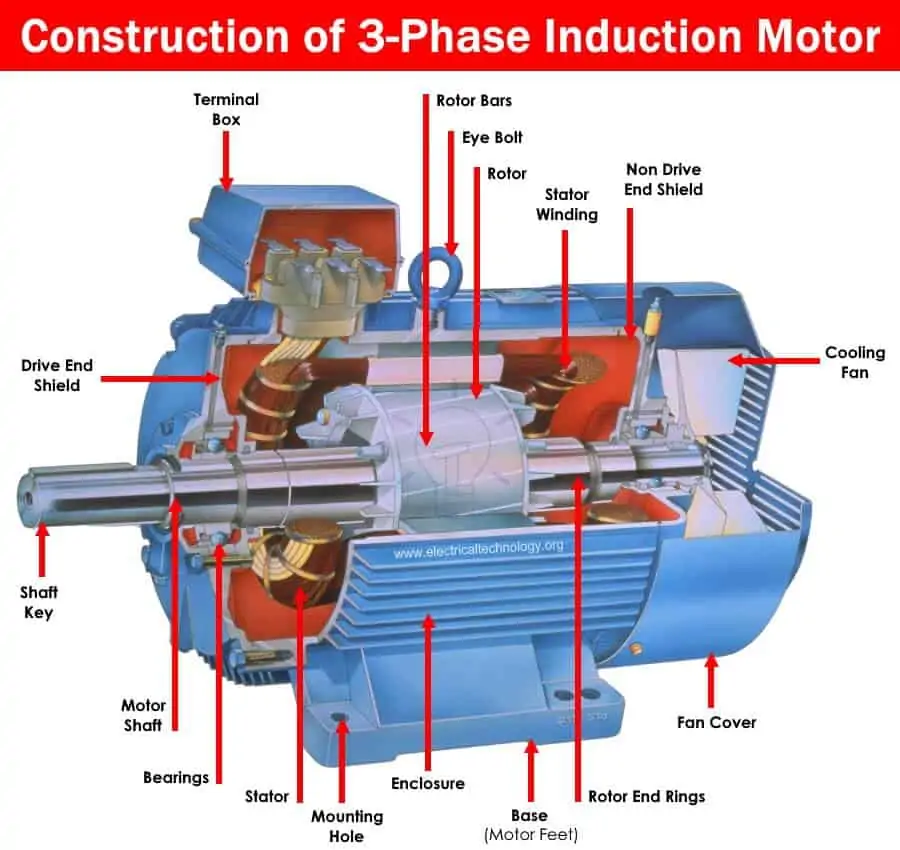

A 3-phase induction motor’s straightforward design, sturdy construction, and great efficiency make it one of the most used electric devices in both daily life and industry. It operates on the electromagnetic induction principle, which states that when a three-phase current passes through the stator (stationary section), a rotating magnetic field is produced. The rotor, or moving component, rotates and generates mechanical motion as a result of the current this spinning field causes in it. When compared to other motor types, these motors are very dependable, low maintenance, and reasonably priced. The 3-phase induction motor, which is frequently found in pumps, fans, compressors, conveyors, and machine tools, is regarded as the “workhorse” of contemporary industries because of its dependability and efficiency.

Working Principle of 3-Phase induction Motor:

A rotating magnetic field (RMF) is created around the stator when the stator windings are powered by a three-phase AC source. The rotor conductors—typically bars in a squirrel cage-style rotor—are severed by this revolving field. This fluctuating magnetic field creates an electromotive force (EMF) in the rotor in accordance with Faraday’s Law of Electromagnetic Induction.

This EMF causes current to flow through the rotor conductors because the rotor provides a closed route. The rotor begins to rotate in the same direction as the stator’s revolving magnetic field due to the force created by the interaction between the rotor current and the field.

Because the current in the rotor is induced rather than supplied directly, this technique explains why the motor is known as a “induction” motor.

More About Here:

Simple Design-

- The straightforward design of a three-phase induction motor is one of its main benefits. It is constructed with fewer parts than other intricate devices, making it more dependable and simpler to comprehend. This simplicity reduces the likelihood of failure and makes maintenance simple even in the event of an issue. Because it doesn’t need costly spare parts or frequent maintenance, this design also lowers the motor’s cost. One of the reasons why industries favor it for heavy-duty applications is its user-friendly design.

Rugged & Durable–

- Because of its reputation for toughness and durability, a three-phase induction motor is ideal for demanding industrial settings. Because of its sturdy design, it can operate continuously without breaking down frequently even under conditions of heat, dust, and high loads. This motor is made to last and function dependably even in harsh conditions, unlike sensitive equipment. Because of its longevity, factories, workshops, and other businesses rely on it for continuous operations, which lowers downtime and repair expenses. In short, it’s a machine that continues to function well under duress.

High Efficiency-

- The great efficiency of 3-phase induction motors is a key factor in their widespread use. With minimal energy lost as heat or vibration, these motors are made to immediately transform the majority of the electrical energy supplied into useable mechanical power. They are ultimately more affordable because they not only guarantee seamless operation but also conserve electricity. Industries rely on them for continuous operations because of their consistent efficiency, even when subjected to enormous loads. To put it briefly, they are both powerful and cost-effective since they produce more with less energy waste.

Self-Starting-

- Self-starting is a major benefit of a three-phase induction motor. A three-phase motor starts itself as soon as electricity is applied, unlike single-phase motors that require extra components like capacitors or starters to get going. This occurs because the rotor is immediately put into motion by the three-phase supply’s inherent creation of a rotating magnetic field. Because no additional starting equipment is required, this function increases the motor’s convenience, dependability, and economy. Because of its hassle-free functioning, enterprises adore employing it.

Cost-Effective-

- Due to its high cost-effectiveness, a 3-phase induction motor is frequently used in commercial and industrial settings. It is less expensive to purchase and install when compared to other motor types with comparable performance. Additionally, over time, its low maintenance requirements and straightforward design keep operating costs low. Over time, it saves money and work because it provides dependable performance without requiring regular repairs or replacements. It is a true value-for-money gadget because of its flawless price-performance ratio.

Low Maintenance–

- The minimal maintenance needed for a three-phase induction motor is one of its key advantages. It doesn’t require frequent maintenance because of its sturdy and straightforward design, which reduces the number of elements that can break or wear out. This makes it a dependable option for continuous operations by lowering downtime and long-term costs for enterprises. The likelihood of damage is low because, unlike other motors, it lacks brushes and commutators. All things considered, it’s a device that guarantees seamless operation while saving time and money.

Smooth Operation–

- The flawless running of a three-phase induction motor is well recognized. It operates silently, producing very little noise and no vibration, guaranteeing steady performance even during extended periods of usage. This lessens wear and strain on the motor itself in addition to improving the comfort of the working environment. It doesn’t shake or make noise when carrying heavy loads because of its balanced design and constant speed. Because it ensures stable and dependable functioning with minimal strain on the system, industries choose it.

Wide Applications–

- One of the most adaptable devices in use today is a three-phase induction motor, which has several uses. Pumps, fans, compressors, elevators, conveyors, and even machine tools are powered by it. It is a favorite in factories, industries, and even huge commercial venues because of its capacity to carry various loads gently and efficiently. This motor effortlessly handles everything from lifting heavy objects to moving water. One of the reasons it is frequently referred to as the backbone of contemporary industry is its versatility in handling different jobs.

Reliable Performance–

- The dependable performance of a three-phase induction motor is well-known, particularly in demanding industrial settings. Its robust structure and effective design allow it to operate continuously for extended periods of time without overheating. For processes that need to run continuously, such as in factories, workshops, or commercial settings, this makes it ideal. Its reliability lowers the likelihood of unplanned malfunctions, saving money and time. It has established a reputation as a machine that industries can depend on day in and day out due to its reliable functioning and consistent output.

Industrial Backbone–

- Because it powers so many equipment, a three-phase induction motor is frequently referred to as the “workhorse of industries.” It keeps industries functioning properly, from heavy machinery and conveyors to pumps and compressors. It is the foundation of contemporary manufacturing and production due to its robustness, effectiveness, and capacity to support constant loads. Many industrial activities would just stop without it. This motor, which is dependable, robust, and adaptable, genuinely lives up to its reputation as the engine propelling industrial development.

3-Phase Induction motor Grape Chat:

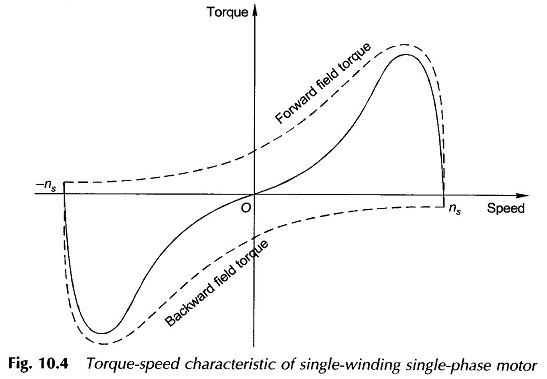

1.Torque vs Speed Characteristic Curve (most common for induction motors):

- Starting Torque: To start big loads, the motor generates a lot of torque while it is at a standstill.

- The maximum torque a motor can manage before slowing down is known as the pull-out torque.

- Stable Operation: Functions smoothly at speeds close to synchronous.

- Significance: Aids in comprehending motor efficiency, performance, and load-bearing capability.

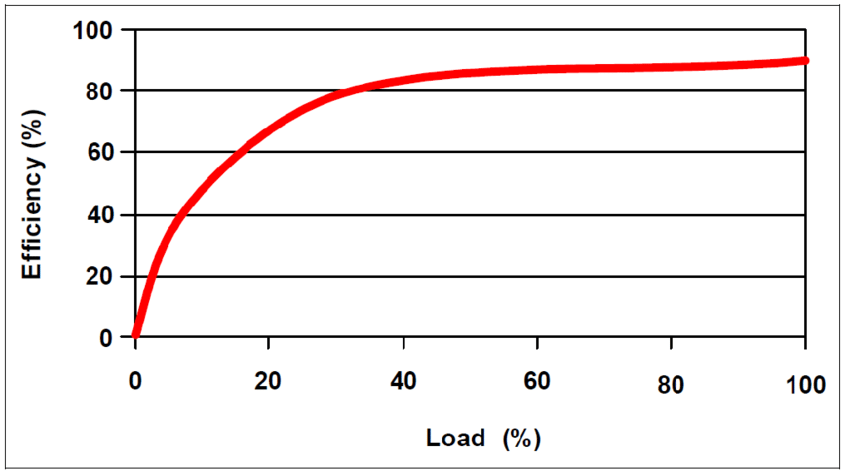

2.Efficiency vs Load Curve:

- The Efficiency vs Load Curve of a 3-phase induction motor shows that efficiency increases as the load rises, reaching its peak at around 75–100% load. At very light loads, efficiency is low due to fixed losses. This curve helps industries run motors at optimal load for best performance.

3.Power Factor vs Load Curve:

- A three-phase induction motor’s power factor vs. load curve demonstrates that, at low loads, the power factor is low because of the increased reactive power. The power factor improves with increasing load and approaches unity at full load. This contributes to increased industrial energy efficiency.